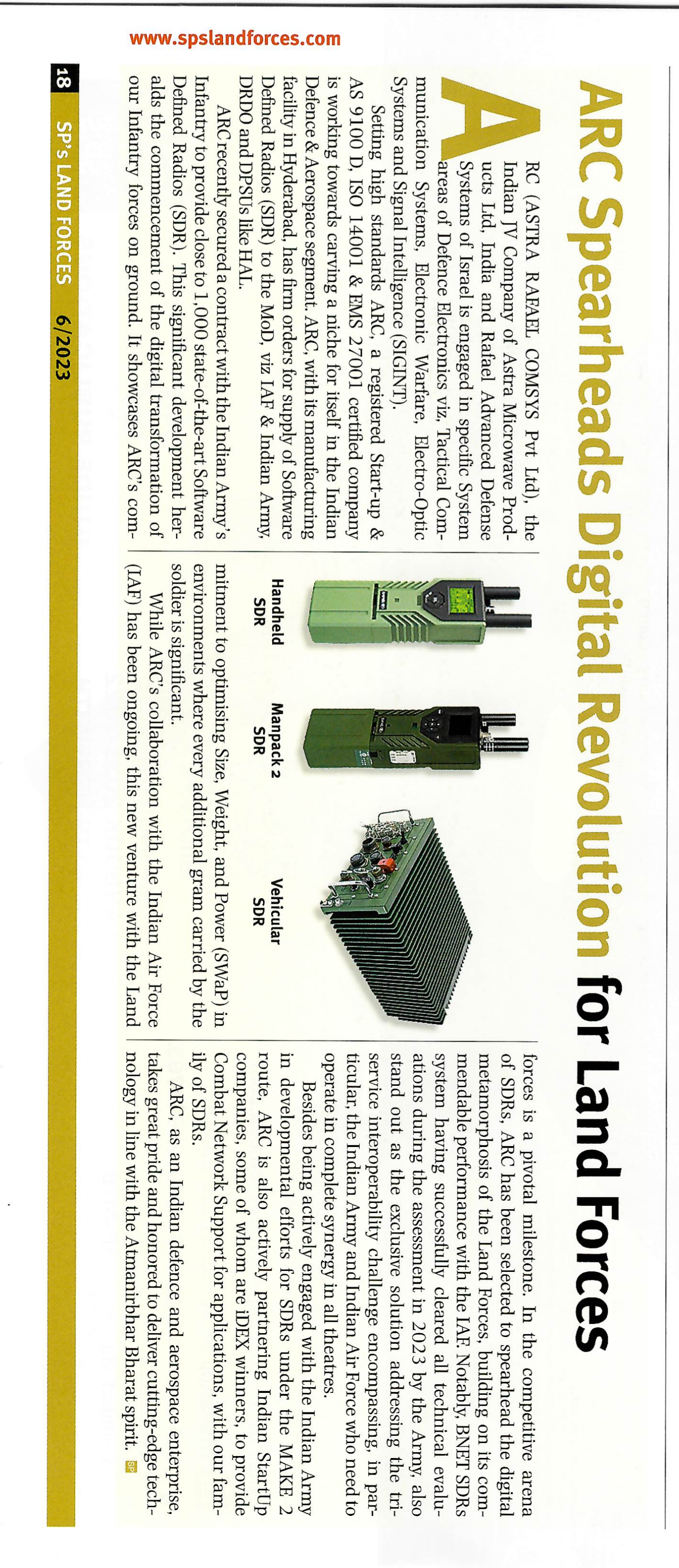

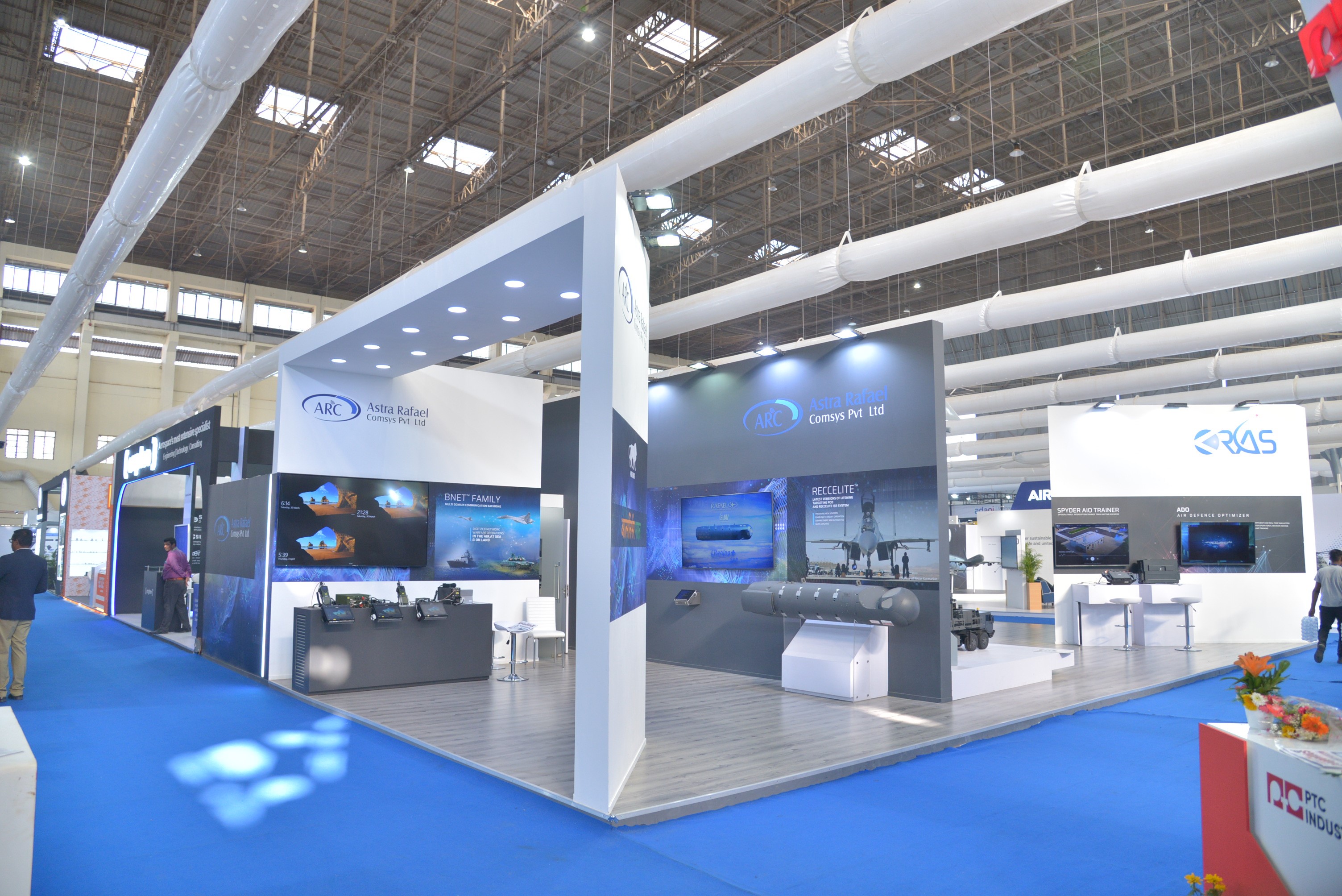

Since the signing of the JV Agreement between AMPL and Rafael, and with the support of both JV partners, ARC completed the build-up of the facility, installation of infrastructure and fixtures in its plant in 2019. The unit has been set up with an investment of several million dollars and ARC has started its operations with awarded contracts and potential market of 100M USD in the next 3 years.

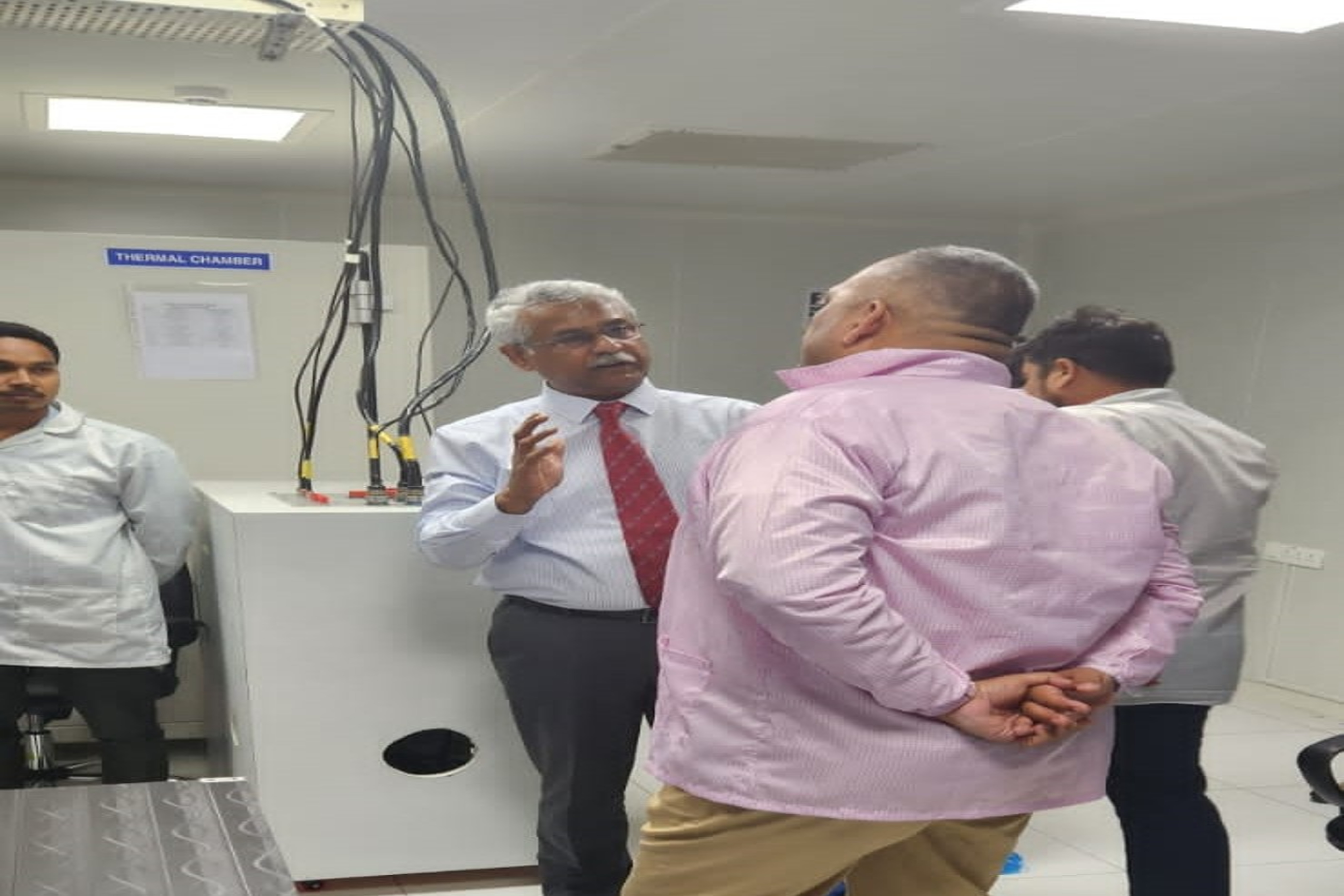

The ARC plant is equipped with state-of-the-art manufacturing set-up with 8000 sq.ft. of Class-1000 Clean-rooms and special area using Class-100 Laminar Flow Stations. It has ESD flooring and furniture to meet electronics manufacturing standards. A world class Reliability Testing facility also has been established to meet the military standards with special equipment's like Environmental Stress Screening Chambers, Multiple Temperature Chambers cum Shaker, Vibration Tables and Specially designed test equipment jigs for testing SDRs. The plant consists of 4 integration and assembly lines (including Support Tests Equipment -STE's) with the impressive capability of producing currently over 50 SDRs per month. This can be ramped up with accretion of manpower, when required.

Industrial License and Security Classification

The facility has been designed to meet the top security classification by adopting highest level of security clearance from the governments (Security Classification ‘A’ and SECRET by Indian and Israel MoD respectively).The company was accorded Industrial License by DIPP, Ministry of Commerce in Dec 2018.

ARC has adopted the world class system of ERP: SAP S4/ Hana, the new generation SAP Business Suite for Digital Enterprise, designed for highest security level with three layer on-premises, physically isolated IT security architecture and physical security measures.

In order to improve production efficiency a sophisticated, Demand Flow Technology (DFT) based storage is implemented which ensures highest possible level of Quality, pre-determined response time, highest possible inventory turns, eliminates non-value add activities (waste) and ultimately increases factory efficiency and flexibility.

The ARC Warehouse is structured to meet ANSI/ESDS20.20-2007 standards. The Warehouse Management System adds efficiency, consistency and quality control. The degree of inventory control is processed in SAP to handle both kinds of inventory viz. raw material handling and finished goods

Manufacturing Infrastructure

State of the Art manufacturing setup, 8000 SFT of Clean Rooms with ESD flooring and furniture that meet global electronics standards.

DFT ( Demand Flow Technology) racks provided to eliminate Non-Value added activities.

STE 1:1 Netcor Test System

ESS Test Set up

(Vibration Test setup +STE 1:1 Tester + Thermal Chamber)